Types of 3D Printing & Which one to choose

In the evolving landscape of manufacturing, 3D printing stands out as a beacon of innovation, paving the way for precision engineered parts. With an array of technologies to choose from, each offering distinct advantages, navigating the world of 3D printing can be as complex as it is exciting. This guide will demystify these technologies, helping you choose the perfect one for your project.

Exploring the World of 3D Printing

The genesis of 3D printing heralded a new era in manufacturing, propelling us towards a future where creating complex, precision engineered parts became not only feasible but routine. From prototyping to final production, 3D printing has opened a vortex of possibilities, democratizing the creation process across industries. This technological marvel, however, is not monolithic; it encompasses various methods, each with its strengths, nuances, and ideal applications.

At its core, 3D printing transforms digital blueprints into tangible objects layer by layer, a method known as additive manufacturing. Unlike traditional manufacturing, which often involves subtracting material, additive manufacturing adds material only where it's needed, dramatically reducing waste and enabling designs that were once deemed impossible. The choice of 3D printing technology can significantly influence the quality, texture, and strength of the final product, making it crucial to understand each method's unique capabilities.

Stereolithography (SLA): Crafting High-Precision Parts

Stereolithography, or SLA, holds the distinction of being the first 3D printing technology developed. It works by curing photopolymer resin with an ultraviolet laser, building objects layer by layer. Renowned for its high precision and smooth finish, SLA is ideal for creating detailed prototypes, intricate jewelry, and precise dental and medical models. While the materials used in SLA are not always suited for end-use products, the technology's ability to produce extraordinarily detailed parts makes it an indispensable tool in the arsenal of engineers and designers alike.

The intricacy achievable with SLA printing is unparalleled, offering the capacity to construct models with complex geometries and thin walls that other methods struggle to replicate. However, this precision comes at the cost of speed and material limitations. SLA printed parts may also require additional post-processing to reach their final form, including washing and curing steps. Despite these hurdles, for projects where detail and finish are paramount, SLA remains the gold standard.

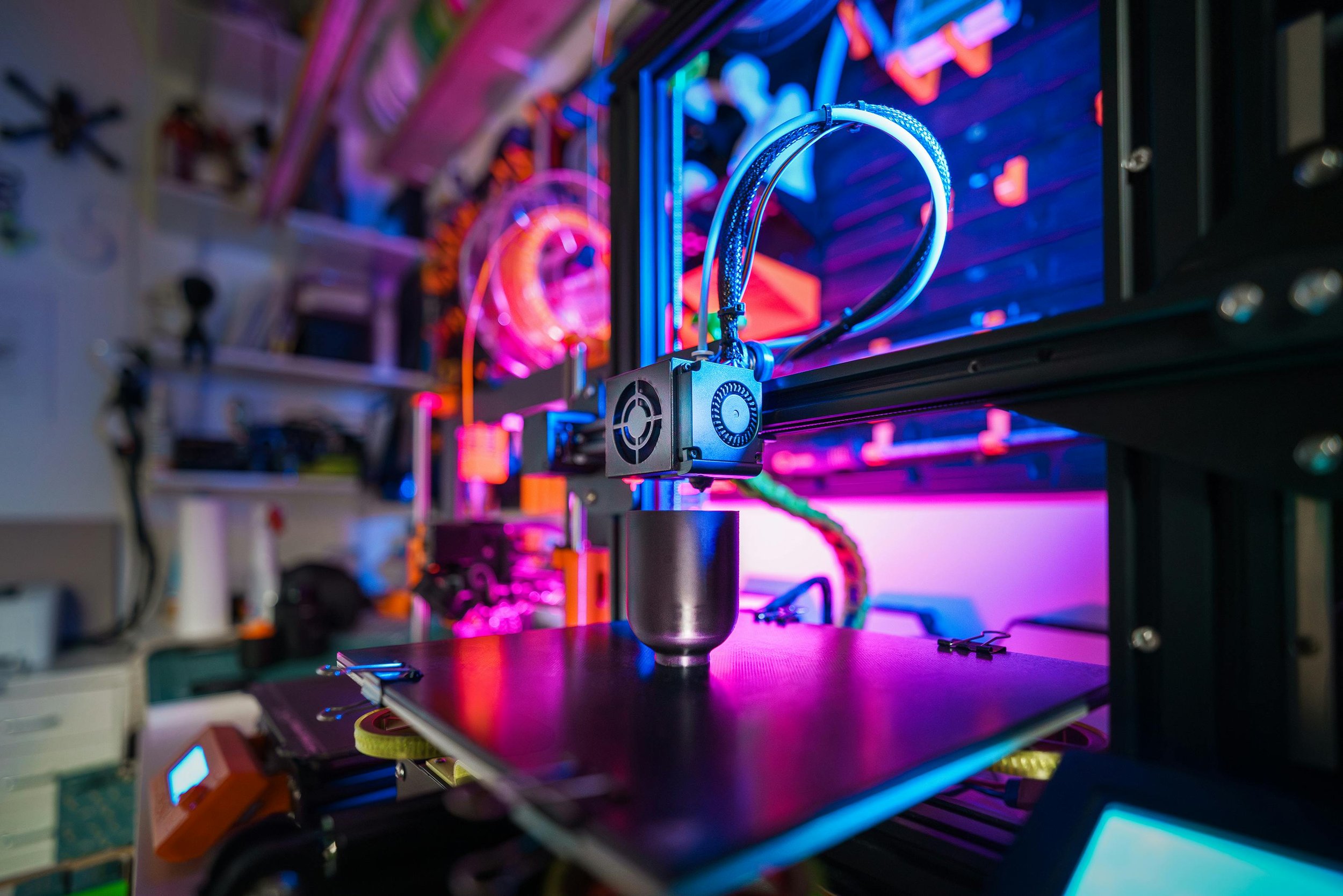

Fused Deposition Modeling (FDM): Versatile and Accessible Printing

Fused Deposition Modeling, or FDM, is perhaps the most widely recognized form of 3D printing, attributed to its ease of use, affordability, and versatility. This technology extrudes thermoplastic filaments, such as ABS and PLA, layer by layer to build an object. FDM printers are prevalent in consumer markets, schools, and hobbyist spaces, making it a familiar entry point for many into the world of 3D printing.

While FDM's accessibility is one of its greatest strengths, it's also known for being less precise compared to technologies like SLA. The layer lines are more visible, and the surface finish may require post-processing for smoothness. However, for functional prototyping, custom tools, and low-cost modeling, FDM offers a balance of quality and efficiency that's hard to beat. Its ability to use a range of materials, including composite filaments, opens up a wide array of applications, from engineering prototypes to functional household items.

Despite its broader layer lines and sometimes rougher finishes, FDM’s strength lies in functional testing. Components printed using FDM can withstand considerable stress, making them excellent for mechanical parts and durable prototypes. Moreover, the technology's support for a diverse array of materials, including flexible, durable, and composite filaments, grants it a versatility cherished by engineers and hobbyists alike.

Selective Laser Sintering (SLS): For Complex and Durable Components

Selective Laser Sintering, or SLS, leverages a powerful laser to sinter powdered material, binding it together to form solid structures. This method is distinguished by its ability to produce parts that are both complex and durable, without the need for support structures. SLS is widely used in automotive, aerospace, and medical industries for creating functional components, including those subjected to high stress and temperature.

The realm of SLS is characterized by its material versatility, allowing the use of a myriad of powders including nylon, polystyrene, and metals. This versatility, coupled with the technology's capacity for high durability, positions SLS as a leader in producing end-use parts and complex assemblies. Moreover, the absence of required support structures enables the creation of geometries that were previously unthinkable, such as interlocking chapters or highly intricate networks.

Digital Light Processing (DLP): Fast and Detailed Prints

Digital Light Processing, or DLP, is a variant of resin printing that uses a digital light projector to cure photopolymer resin. Like SLA, DLP produces parts with a high degree of precision and a smooth finish but at a significantly faster pace. The technology shines in applications requiring rapid prototyping and the production of detailed models, such as in the dental industry or character modeling for film and animation.

DLP's strength lies not just in its speed and detail but also in its efficiency, utilizing a projector to cure entire layers at once, significantly reducing printing time compared to point-by-point curing methods. This efficiency, however, requires the management of resin properties and may lead to variations in part performance depending on the chosen material. Nevertheless, for projects demanding quick turnaround times without sacrificing detail, DLP is an invaluable technology.

Choosing the Right 3D Printing Technique for Your Project

The journey through the diverse landscape of 3D printing technologies ends with a crucial decision: choosing the right method for your project. The selection process hinges on understanding the specific requirements of your project, including the desired precision, material properties, and functional purpose of the parts being produced. Whether you prioritize the intricate detail afforded by SLA and DLP, the durability and versatility of SLS, or the accessibility and range of FDM, the optimal choice aligns with the unique demands of your application.

Considerations such as budget, speed, and post-processing requirements also play a significant role in this decision. For example, while technologies like SLA and DLP offer superior finishes, they may require extensive post-processing. On the other hand, FDM and SLS provide robust parts with minimal post-production work but may not achieve the same level of detail. Ultimately, the choice of 3D printing technology must balance the aesthetic and functional needs of the project, ensuring that the final product not only meets but exceeds expectations.

Empowering Innovation with the Right Choice

Choosing the right 3D printing technique is pivotal for achieving optimal results in manufacturing precision engineered parts. As we've explored, technologies like SLA, FDM, SLS, and DLP offer unique benefits, from high precision to durability and speed. Your project's specific requirements—be it detail, strength, or material properties—will guide you in selecting the method that not only meets but exceeds your expectations, revolutionizing how you approach manufacturing and design.